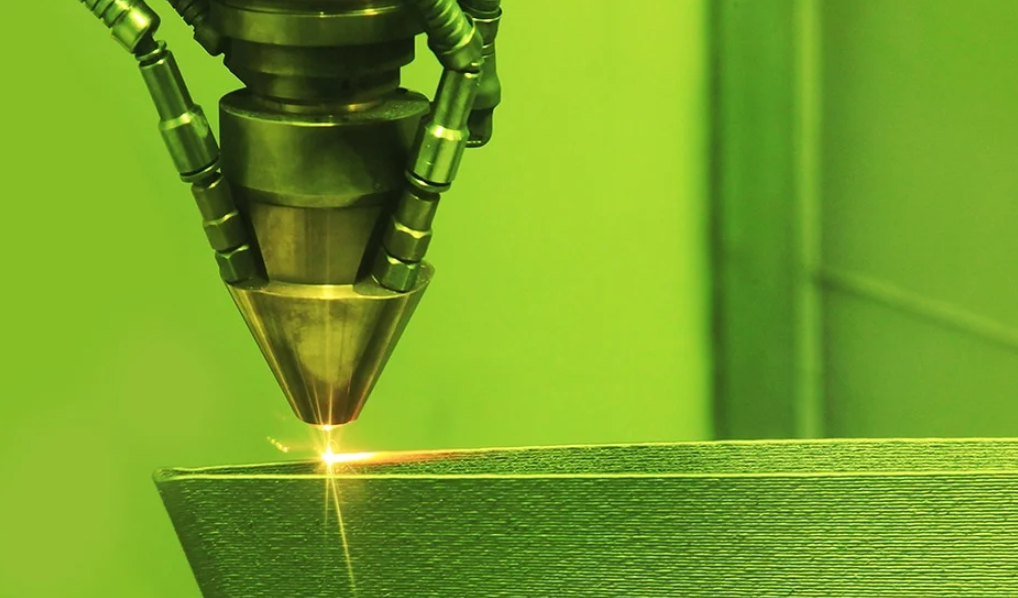

Laser rapid prototyping technology is a type of 3D printing that uses lasers to selectively melt or fuse materials together to create a 3D object. This technology uses computer-aided design (CAD) software to design and create complex, geometrically-shaped objects by layering materials on top of each other.

The laser rapid prototyping process starts with a 3D CAD model of the object that you slice into multiple layers. Then the laser rapidly and precisely scans each layer fusing the material together in the desired shape. You can repeat the process layer by layer until you have the complete 3D object formed as guided by prototyping services china.

Importance of choosing the right technology for a project

For any laser rapid prototyping project to be successful, you have to be very intentional and choose the right technology that matches the project. Remember this will depend on the expected functionality of the project.

So, some of the reasons why choosing the right laser technology is important are:

Material Compatibility

Different rapid prototyping technologies are better suited for different materials. Therefore, choosing the right technology can ensure that the materials you use are compatible with the final product’s requirements.

Budget

If you choose the right technology you can be sure the production will remain within your estimated budget or even scale much lower than what you thought. This is because with the correct production you will have minimized lots of wastes.

Product Complexity and Efficiency

Choosing the right technology for your project will help improve efficiency by reducing production time, minimizing waste, and lowering costs. It will also increase the accuracy and consistency of the final product, which can save your time and money in the long run.

In addition, some rapid prototyping technologies are better suited for creating complex shapes and structures than others. So, choosing the right technology for your project can help you produce a more accurate and consistent prototype, which can save time and money in the long run.

How to Choose the Right Laser Rapid Prototyping Technology for Your Project?

There are different laser technologies available for a wide range of applications today. So this makes choosing the right laser rapid prototyping technology for your project challenging. Here are some steps you can follow to make an informed decision:

Evaluate Available Technologies

You’ll need to research and compare different laser rapid prototyping technologies to determine which ones are best suited for your project requirements. Some popular laser rapid prototyping technologies include stereolithography (SLA), selective laser sintering (SLS), and direct metal laser sintering (DMLS).

Consider Material Compatibility

Laser rapid prototyping technologies are compatible with different materials, including plastics, metals, and ceramics. So you need to ensure you choose a technology that is compatible with the material you plan to use for your project.

Evaluate Accuracy and Resolution

The accuracy and resolution of a laser rapid prototyping technology are critical for you to achieve the desired outcome. So, you’ll need to consider the level of accuracy and resolution needed for your project and choose a technology that can deliver the required level of precision.

Conclusion

In conclusion, choosing the right laser rapid prototyping technology for your project involves considering your project requirements, evaluating available technologies, assessing material compatibility, accuracy and resolution, production speed, and cost. So by following these steps, you can make an informed decision and ensure the success of your project.